Optimizing the power pathway from grid to chip

Applications such as artificial intelligence (AI) and machine learning (ML) are increasingly integrated into society, largely enabled by the exponential growth in computing power that is made possible by the latest generation of semiconductors and data centres. The broad buildout of power-hungry, accelerated computing platforms is placing intense demand on data centre power consumption. The International Energy Authority predicts that energy demand from data centres could surpass 1,000 TWh in 2026, equivalent to the total amount of electricity consumed by Canada, Poland and Argentina combined in 2023.

Data centre power

Operators need access to more power sources and the ability to efficiently distribute more of this power from the grid, through the facility and rack, and ultimately to the chip. That said, the capital costs of computing hardware, power supplies, power distribution and cooling systems must be minimised, so must the environmental impact and monetary cost of the energy consumed. Data centre operators are under pressure to maximise return on investment and they are seeking a competitive edge in infrastructure optimisation. This means that the electrical and cost efficiency of the power conversion process must be maximised.

Power system architectures are constrained by many factors. For example, the trend towards lower voltages and higher currents at the chip level means that the final conversion stage must be very close to the load to ensure minimum voltage drop and disturbances due to connection inductance and to cope with the higher load transient requirements of the latest processors. This, in turn, places the power conversion electronics close to the kW level dissipation in the processors, potentially producing challenging cross-heating in an already highly space-constrained area.

Upstream power conversion from voltage regulator modules at the processors must be done in stages using a distributed power arrangement. This approach involves utility-connected AC/DC converters, backup power systems and one or more intermediate buses with associated power converters operating at voltages that keep currents at manageable levels. This helps minimise interconnection sizing, cost, power losses and voltage drops.

Cooling and isolation

Key design considerations also include how to integrate the power converters within the data centre’s cooling infrastructure, as well as decisions on whether and where to provide galvanic isolation in the power conversion train given potential concerns about ground loops and safety. Physical space used by power conversion and distribution equipment within the data centre is an issue. Placement of equipment is strongly influenced by the cooling it needs, which is defined by its electrical efficiency and power density.

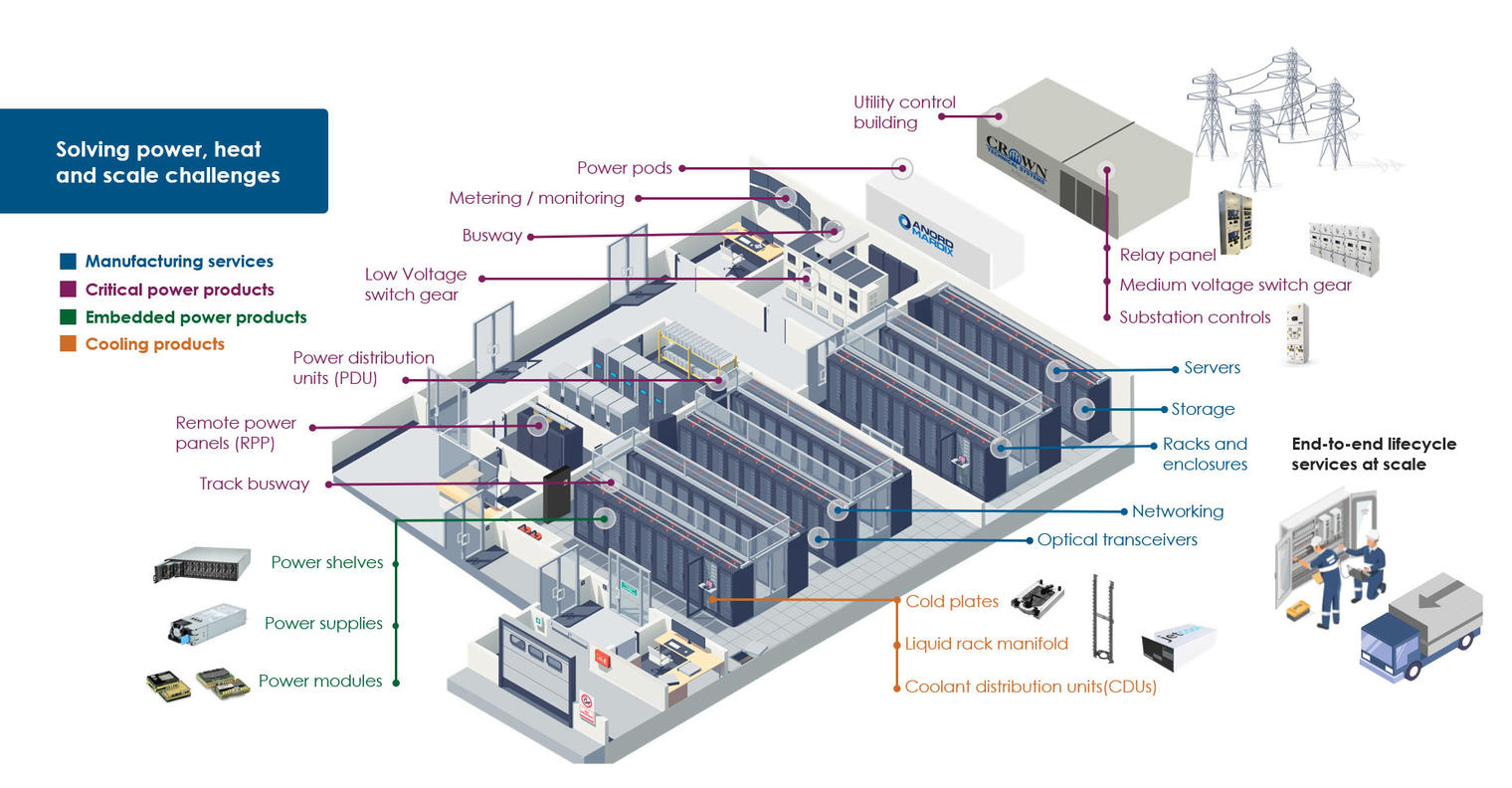

Picture: Flex grid-to-chip offering

Power distribution technologies within a data centre vary widely, encompassing everything from AC grid transformers and switch gear to mechanical busbars and high-frequency DC/DC converters operating up to MHz levels. As a result, the trade-offs can be difficult to evaluate and, in some cases, are subjective.

For example, a system architect might advocate for distributing power at 800Vdc rather than 48Vdc to reduce currents, power losses and voltage drops, and enable the use of smaller, more cost-effective busbars and cabling. Safety engineers, however, would counter that there would now be compliance requirements at the higher voltage, with associated costs in extra insulation, isolation and ongoing certification. Engineers and technicians working at the higher voltage would need to hold appropriate qualifications to ensure their own safety and that of other data centre employees and users. In contrast, bus voltages at 48Vdc are supported by a wealth of existing products offering multiple sources and cost advantages due to economies of scale. They are also inherently safe, being below the safety extra low voltage limits.

Another important trade-off to consider is whether the intermediate bus voltages should be regulated or unregulated. The latest isolated, but unregulated, designs can offer superior efficiency and power density, but they require careful selection of downstream converters to ensure compatibility. There are even hybrid regulation options where the bus voltage is permitted to vary within predefined limits, with active control engaging beyond only these thresholds. This approach provides greater flexibility for downstream converters while maintaining efficiency.

A holistic approach

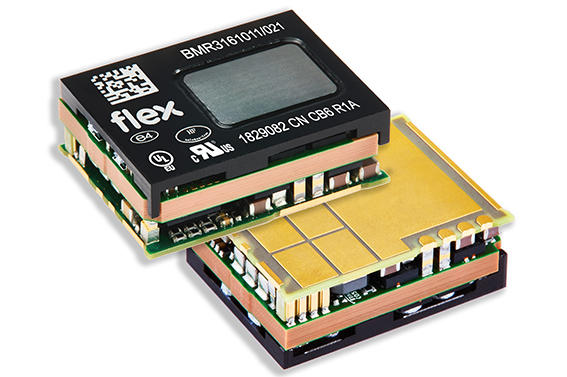

Identifying the optimal solution for grid-to-chip power conversion and distribution requires a holistic approach. Even the conventional power tree may no longer be appropriate, as the boundaries between power conversion elements have become increasingly blurred. For example, DC/DC converters are now closely integrated electrically and thermally with processors using vertical power delivery technologies tailored to match the unique pin-out configurations of individual processors.

Picture: BMR316

When components of the power conversion chain are sourced from different vendors, there is a significant risk of incompatibility. Additionally, with each supplier promoting its own proprietary technology, achieving a holistic solution can be challenging. A power conversion specialist, which takes responsibility for optimising compatibility, cost and performance, has advantages and can offer guidance and long-term support.

Some offer an end-to-end portfolio, including data centre power and cooling products, including DC/DC regulators and bus converters, and solutions for medium and low voltage AC/DC conversion, power distribution, critical backup power systems, and rack- and chip-level cooling. They can also provide custom designs, including vertical power delivery configurations and simulation tools to model systems prior to implementation. Comprehensive monitoring and support also ensure performance and reliability.

With the voracious need for data centre power showing no signs of abating, data centre operators must rely on companies with the design, product, manufacturing, supply chain, systems integration and open ecosystem experience needed to collaborate and scale to support roadmaps and ensure that data centre upgrades and capacity come online when required.

Did you know?

Vertical power delivery in the spotlight

Vertical power delivery (VPD) helps manage power in data centres by boosting efficiency and reliability and significantly reducing energy loss.

Traditional lateral power delivery methods often lead to considerable power dissipation across the PCB, increasing energy costs and complicating thermal management.

In contrast, VPD shortens the power transmission path by placing voltage regulators directly beneath high-performance processors. This closer proximity minimises power plane resistance, enhances current density and dramatically lowers power losses. VPD designs that enable direct underside connections to processors and ASIC power pins further optimise efficiency and performance.

Liquid cooling continues to make inroads

While accelerated compute platforms have introduced power requirements to data centres, the heat they generate has created a massive challenge for cooling solutions.

Direct-to-chip cooling transfers heat from processors to liquid-cooled cold plates. In data centres, this approach can significantly outperform forced air cooling in heat transport/removal and make board design more flexible, eliminating the need to place processors and heatsinks near an air exit.

JetCool (a Flex company) also uses microjet technology, precisely targeting hotspots to improve cooling efficiency at the chip level.

Managing continuous power

Reliable, scalable power is essential for ensuring data centres avoid downtime and data loss and retain high efficiency and security. The risks of power failure, load imbalances and inefficient distribution can result in significant consequences, from service outages to overheating and equipment failure. Pre-fabricated modular systems, such as those developed by Anord Mardix (a Flex company) can eliminate time-consuming and costly modifications to data centre expansion plans. They integrate essential components, such as transformers, switchgear and uninterruptable power supply systems into a compact, pre-tested assembly that can be quickly installed to minimise disruptions.

With courtesy of Electronics Weekly Review