The Swedish innovations that power AI

Sweden has a long history of ingenuity and is responsible for world-changing inventions such as the zipper, the three-point car seat belt, the adjustable spanner, the tetrahedral-shaped drinks carton, and the first implantable pacemaker[1]. Bringing us closer to the present, our lives would be very different without another Swedish-led breakthrough, the Bluetooth wireless standard. Today, companies such as Spotify, Klarna, and Hexagon – alongside eye-tracking software pioneer Tobii – continue to make global headlines as leading examples of the country’s innovation.

What is it like for businesses developing new technologies in Sweden, and how can they recruit and retain the expertise they need to stay ahead?

Henrik Borgengren of Flex Power Modules knows these challenges first-hand. As R&D Director at the Flex design facility in Kalmar, southern Sweden, he has overseen the business quadruple in size in recent years, with its growing workforce central to that expansion.

“We’ve grown, with more than three times the number of employees we had on our team just a few years ago,” says Borgengren. “As the engineering team expands, we complement the organization with specialists who bring niche competence in specific areas. It’s a holistic approach, where our people see a product through every stage of development – which helps us attract and retain top talent.”

Yet Flex Power Modules is more than a single R&D base in Sweden. Its second site in Shanghai mirrors the activities of Kalmar and continues to grow rapidly. And it’s part of Flex, one of the world’s largest manufacturing companies, which is playing a pivotal role in advancing technologies that enable AI innovation.

Industry trends led by AI

Today’s technology industry is changing even faster than before – with AI dominating daily conversations, and promising dramatic changes in our everyday lives. All these AI systems, typically running in large hyperscale data centers, need systems to power them efficiently and reliably – a critical opportunity for a power specialist like Flex.

“If I just go back three years, we were focusing on RFPA and telecom products and we had many teams working with that, as well as of course some data center activities,” says Borgengren.

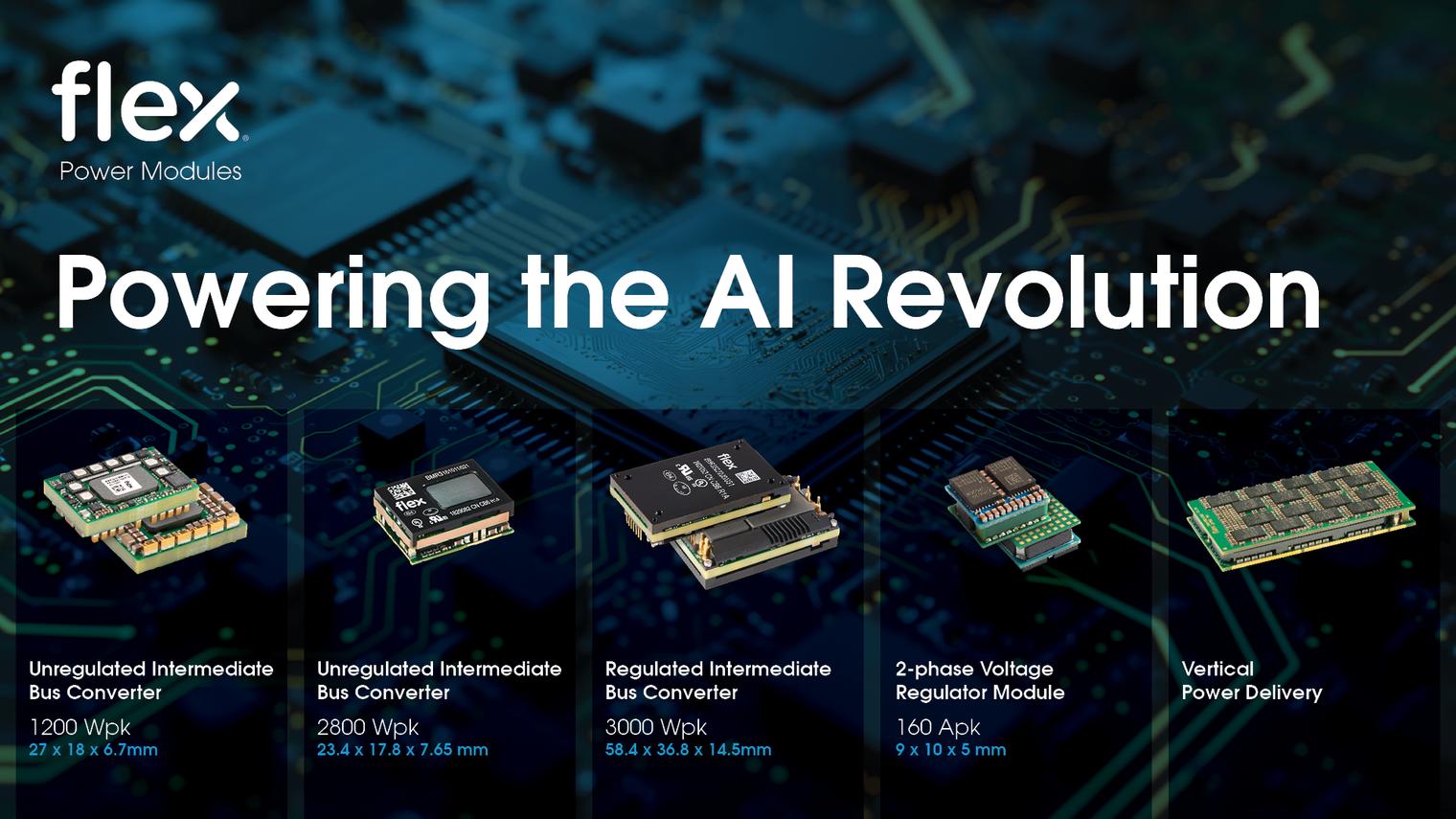

“But over the last two years, our focus has shifted strongly to data center products – building solutions for the big hyperscalers and powering their xPU boards,” continues Borgengren. “We’re a key part of the AI transformation, with our custom designs using vertical power delivery (VPD) technology to power the high-performance AI chips.”

As part of this shift to AI, Flex Power Modules has become an expert in custom power designs. Borgengren acknowledges that today the majority of the company’s technical teams now focus on AI based customized power solutions.

For these products the need, for higher power density is relentless – squeezing more power into less space. Borgengren says, “This challenge extends beyond the modules themselves, with the infrastructure for testing and validation also becoming much more complex.”

Holistic design and team structure

Kalmar’s facility has grown rapidly, with a lab expansion accompanying the workforce tripling in the past few years. Flex Power Modules has a portfolio of around 1,250 products.

The company uses a holistic design approach and team structure. A ‘whiteboard method’ ensures comprehensive knowledge is shared across the entire team rather than isolating expertise in silos.

“We develop our power solutions from start to finish – from initial research, through simulations, production, qualification to product release, and after-sales support,” says Borgengren. “It means our engineers can see the full impact of their work. I call them super-teams: they can drive a project from beginning to end.”

AI simulations accelerate development

AI isn’t just the biggest growth market for Flex’s products – it is also shaping how the company develops them, how it operates and its ability to scale. Software simulations save development time, with ‘digital twins’ modeling real-world components. The team makes extensive use of ‘virtual prototyping’ which involves simulating electrical, thermal, and structural aspects before building power solutions.

“Digital twins allow us to simulate a product before we build it, which is very beneficial during the design process. Over the past three years we’ve invested a lot of effort in strengthening our proprietary simulations, and our ability to validate them,” says Borgengren.

This work also helps Flex Power Modules' customers, as the company’s Flex Power Designer (FPD) software provides an accurate, powerful simulation tool, including sophisticated thermal models.

Flex Power Modules also uses simulations in the extensive tests that it runs on its power modules, to help ensure they can meet specifications under extreme conditions. These typically use load simulators rather than actual chips, given the practical challenges of mounting and readiness.

“We follow standard testing procedures, including shock vibration and climate testing, with particular emphasis on moisture sensitivity level qualification and temperature cycling for materials,” says Borgengren. “We have implemented additional internal testing beyond standard Open Compute Project requirements, to exceed typical industry levels.”

What’s new in power technology?

In terms of architecture trends, Flex Power Modules is pushing the envelope in multiple areas of power system designs, with its research developing new technologies and products. For instance, it’s working on low voltage systems using very high currents of 2000A or more. This brings new challenges, as Borgengren explains: “At these high currents, we start to see the phenomenon of electromigration, where atoms in a conductor move due to the flow of current. This can cause reliability problems from uneven distribution of the atoms.”

“To test components and materials, including for these kinds of challenges, we need to use specialized equipment – such as the latest high-precision scanning machines – for precise analysis in constrained spaces,” says Borgengren. “There are very few of these machines anywhere in the world. Soon, we’ll be able to scan almost at a molecule level, effectively looking inside solid materials to get an extremely detailed picture of what’s going on.”

Another area where design work is pushing the limits of the industry’s capability is in handling the extreme demands of start-up power peaks and in-rush sequencing in converter systems. Borgengren explains, “When a system starts up, it needs to be done in a very specific way, and we use software to manage capacitor banks and prevent overcurrent protection issues at startup – another area where simulation is vital in our work.”

Liquid cooling is also an area that’s becoming increasingly important, with the high-power density of VPDs meaning liquid is preferred over air cooling. Borgengren says, “With good liquid cooling, you can control the temperature in a very precise way – so being able to design our own liquid controllers is an advantage, as well as having suitable testing and verification capabilities.”

“Our latest cooling blocks are performing at an industry-leading level. In addition, we work with JetCool, a Flex company, to deliver cooling and server technology, to support the most demanding AI workloads with unmatched efficiency and scalability.”

He concludes: “As we grow our team and improve the accuracy of our simulations and models, we’re able to attract more customers and scale the business.”