Power design challenges with unregulated IBC

Introduction

As demand for data centers increase particularly for those dedicated to serving AI computational needs, power supply systems must not only continue to deliver improved efficiency but also power density.

Data center power architectures have been evolving to address the rise in demand and changing load requirements. Previously, each rack shelf had its own AC/DC converter, leading to bulky and costly wiring. Nowadays, an Intermediate Bus Converter (IBC) streamlines the process with a bulk AC/DC converter supporting an entire cabinet, delivering DC power usually at safe voltages of 48V or 54V to minimize ohmic (I2R) losses and maintain acceptable current levels.

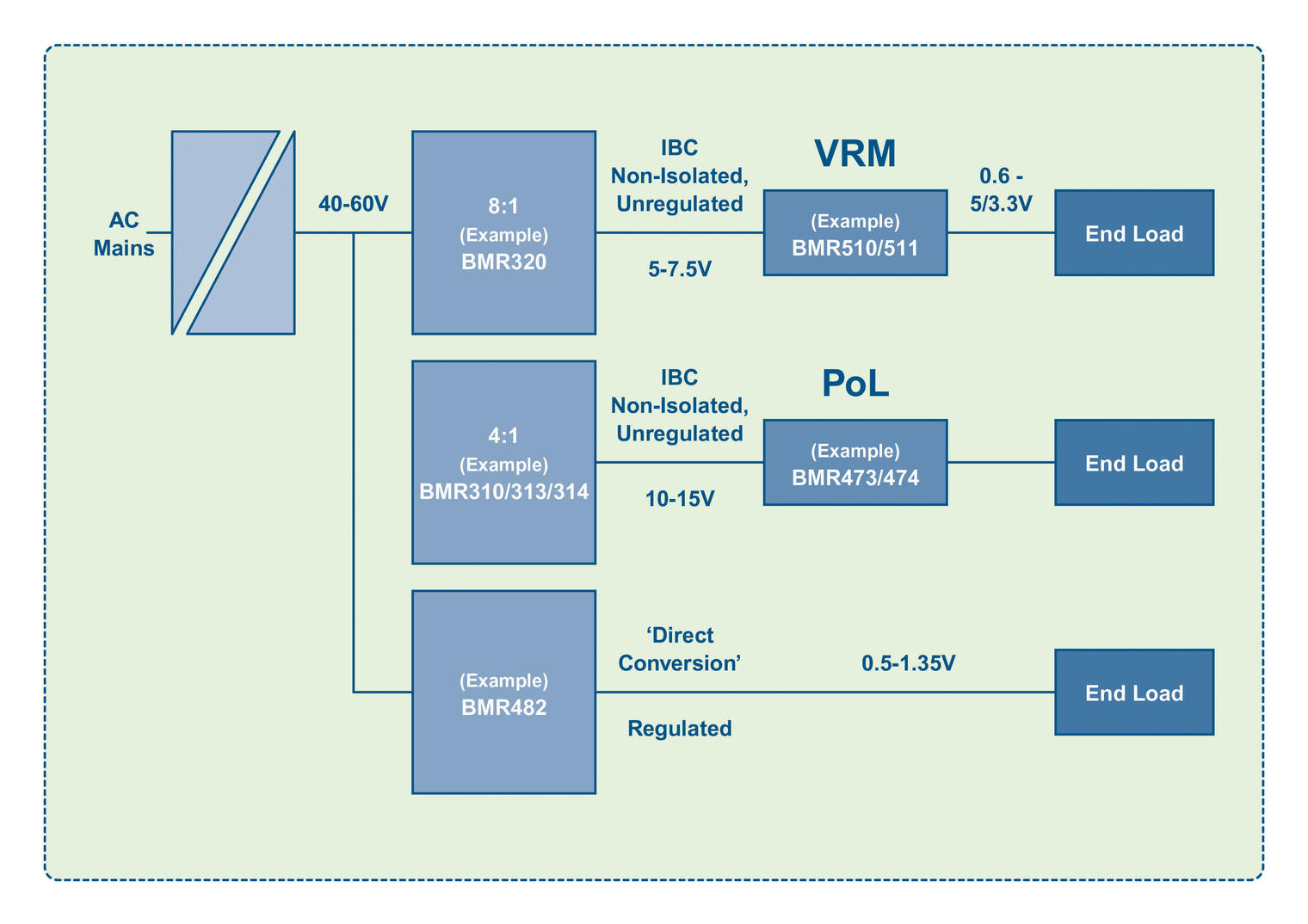

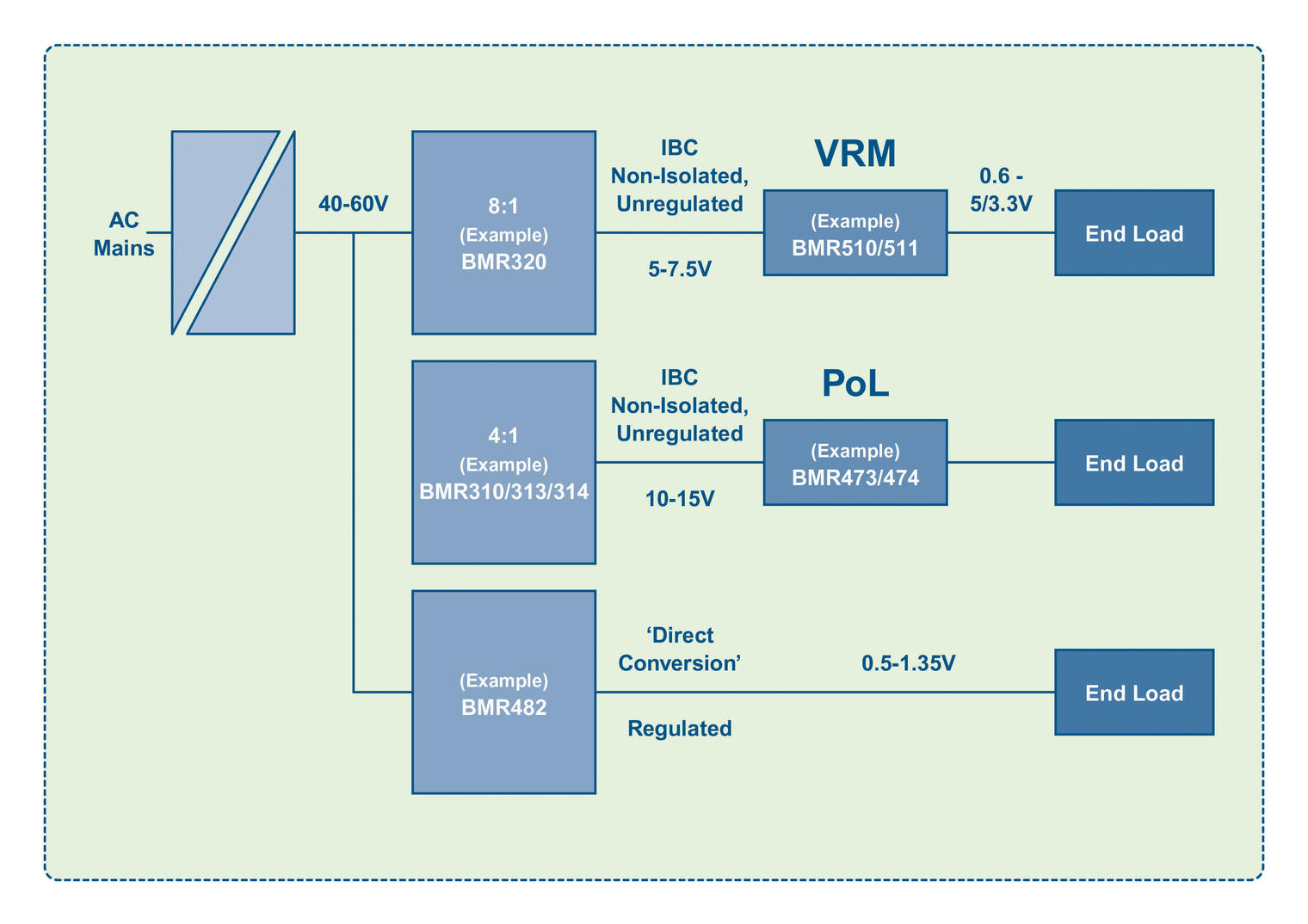

Within each blade, an IBC transforms the 48V input to an intermediate bus voltage (often 12V), which then passes through point-of-load (PoL) converters or more recently Voltage Regulator Modules (VRM) to achieve the precise voltages required for various boards and chips at the high currents often demanded. Traditionally, IBCs have had to be compatible with the 36V to 75V range used in telecommunications applications, but since the data center environment no longer uses battery back-up (more usually uninterruptible power supplies are used), the input voltage of the IBC can be optimized to 40V to 60V or an even tighter range.

There are many advantages of adopting an IBC-based system, including higher efficiency, lower cabling costs, and better power density. However, introducing an additional conversion stage means the benefit of efficiency becomes most paramount.

The lowdown on choosing unregulated IBCs

Flex Power Modules has developed different types of IBCs such as unregulated, regulated, and the innovative hybrid regulated ratio (HRR) option. Designers must evaluate considerations such as cost, efficiency, and specific system needs to select the most suitable approach.

Unregulated IBCs have a fixed conversion ratio, such as 4:1 (meaning a 48V input converts to a 12V output), which enables them to achieve the highest efficiency, lowest cost, and smallest size. However, their output voltage is directly proportional to the input voltage, which means the PoL converter must be able to handle potentially large voltage variations.

Regulated IBCs, on the other hand, use a feedback or feedforward loop to control its output voltage within much tighter tolerances – but this means that the IBC has lower efficiency than its unregulated alternative. Nonetheless, keeping to a small output voltage range can significantly improve the efficiency of the PoL converter.

Figure 1: DC-DC converter architectures

The HRR model blends both approaches, providing proportional regulation up to a set input voltage before switching to full regulation, combining the best features of both systems for many applications.

Overcoming IBC design challenges

Within these different approaches, there are multiple technical challenges that must be addressed to achieve an efficient, reliable IBC design.

Start-Up dynamics: Initial power application can spike ripple currents, potentially damaging components or tripping over-current safeguards. Regulating the switching frequency or employing larger output inductors can mitigate this.

Synchronous rectification: This method boosts efficiency by substituting diodes with MOSFETs for rectification, which have lower voltage drops. However, it introduces complexity, especially regarding converter drive timings.

Reverse energy management: MOSFETs can conduct current in either direction, posing risks during abrupt shutdowns. Proper control strategies, including timely MOSFET deactivation, are crucial to prevent unwanted reverse current flows.

Many engineers prefer to procure complete IBC modules from manufacturers, designed to meet these challenges whilst maximizing both performance and efficiency.

Implementations in practice

Flex Power Modules has introduced non-isolated unregulated IBC solutions such as the BMR313, BMR314, and BMR320.

The BMR313 model excels in confined spaces, offering a 3kW peak in a miniature form (23.4 x 17.8 x 7.65 mm), achieving a remarkable 908 W/cm³ power density with an input to output ratio of 4:1. The BMR313 leverages the advantages of the FD6000, onsemi’s latest generation, intermediate bus digital controller. At an input voltage of 54 V, the module’s efficiency is as high as 97.2% at 50% load (40 A).

Another example of a non-isolated, unregulated 4:1 ratio IBC is the BMR314, which delivers up to 1.5 kW peak power. As with the BMR313, the BMR314 uses an industry standard LGA footprint and pin-out for security of supply and second sourcing.

Figure 3: Flex Power Modules’ BMR314

Additionally, the BMR320 is suitable for 40V to 60V inputs, and utilizes an 8:1 fixed ratio, which means that the output voltage ranges from 5 V to 7.5 V. This makes it ideal for applications that require a lower intermediate bus voltage that can be helpful to optimize overall system efficiency, when used in conjunction with downstream PoL converters, VRMs or Integrated Power Stages such as the BMR510 and others.

Each module is equipped with a PMBus interface for ease of monitoring, configuration, and control, seamlessly integrating with Flex Power's Designer software to facilitate sophisticated power system management.

Conclusion

Unregulated IBCs are increasingly popular in data center applications due to their superior efficiency and cost-effectiveness compared to regulated types.

Alongside the 4:1 and 8:1 input to output ratios mentioned previously, other ratios are being requested which allow system designers to optimize their overall system efficiency. Examples include 5:1, 6:1 and even 10:1, which Flex Power Modules is responding to through new product developments utilizing the latest topologies and component choices, as well as novel thermal management techniques to enable the highest power densities.

As demand for more robust and efficient power supplies continues to grow – driven by advancements in processor technology geared towards AI applications – power design engineers will maintain their focus on thermal management at high power densities, as they try and keep cooling costs down.

Fortunately, Flex Power Modules remains a global leader in IBC power modules, continually innovating to meet these evolving needs with reliable and efficient power solutions.